Table of Contents

Introduction – Purchase vs Procurement

In the dynamic landscape of modern business, effective resource management is crucial for operational success. Central to this is an understanding of two key concepts: purchase and procurement. While often used interchangeably, each term embodies distinct processes and strategic elements that are vital for organizations. By grasping the difference between purchasing and procurement, organizations can streamline their operations, enhance supplier relationships, and position themselves for sustainable growth. This article will dive into the definitions, differences, processes, and strategic importance of purchase and procurement, as well as their benefits and real-world applications.

Defining Purchase and Procurement

What is Purchase?

Definition and Explanation

Purchasing refers to the specific act of acquiring goods or services in exchange for payment. It is primarily transaction-focused and typically involves the direct buying of products or services to meet an immediate need. Purchasing is often executed by operational staff within organizations, and it represents a tactical function in the broader supply chain management process.

Examples of Purchasing Activities

– Buying Office Supplies: An office manager places an order for paper, pens, and printer ink to keep day-to-day operations running smoothly.

– Retail Transactions: A supermarket places an order for fresh produce to restock its shelves.

– Bulk Orders: A manufacturing unit purchases raw materials in large quantities to maintain production flow.

What is Procurement?

Definition and Explanation

Procurement is a comprehensive process that encompasses all activities involved in obtaining goods and services, from initial planning to final acquisition. This process includes identifying needs, sourcing suppliers, negotiating contracts, and managing supplier relationships. Procurement is strategic in nature, spanning beyond mere transactions to incorporate long-term planning and risk management.

Examples of Procurement Activities

– Supplier Selection: Assessing and choosing suppliers based on quality, cost, and reliability to ensure a sustainable supply chain.

– Contract Negotiation: Deliberating terms and conditions with suppliers to establish mutually beneficial agreements.

– Ongoing Supplier Management: Engaging with vendors for performance assessments and resolving issues that may arise throughout the partnership.

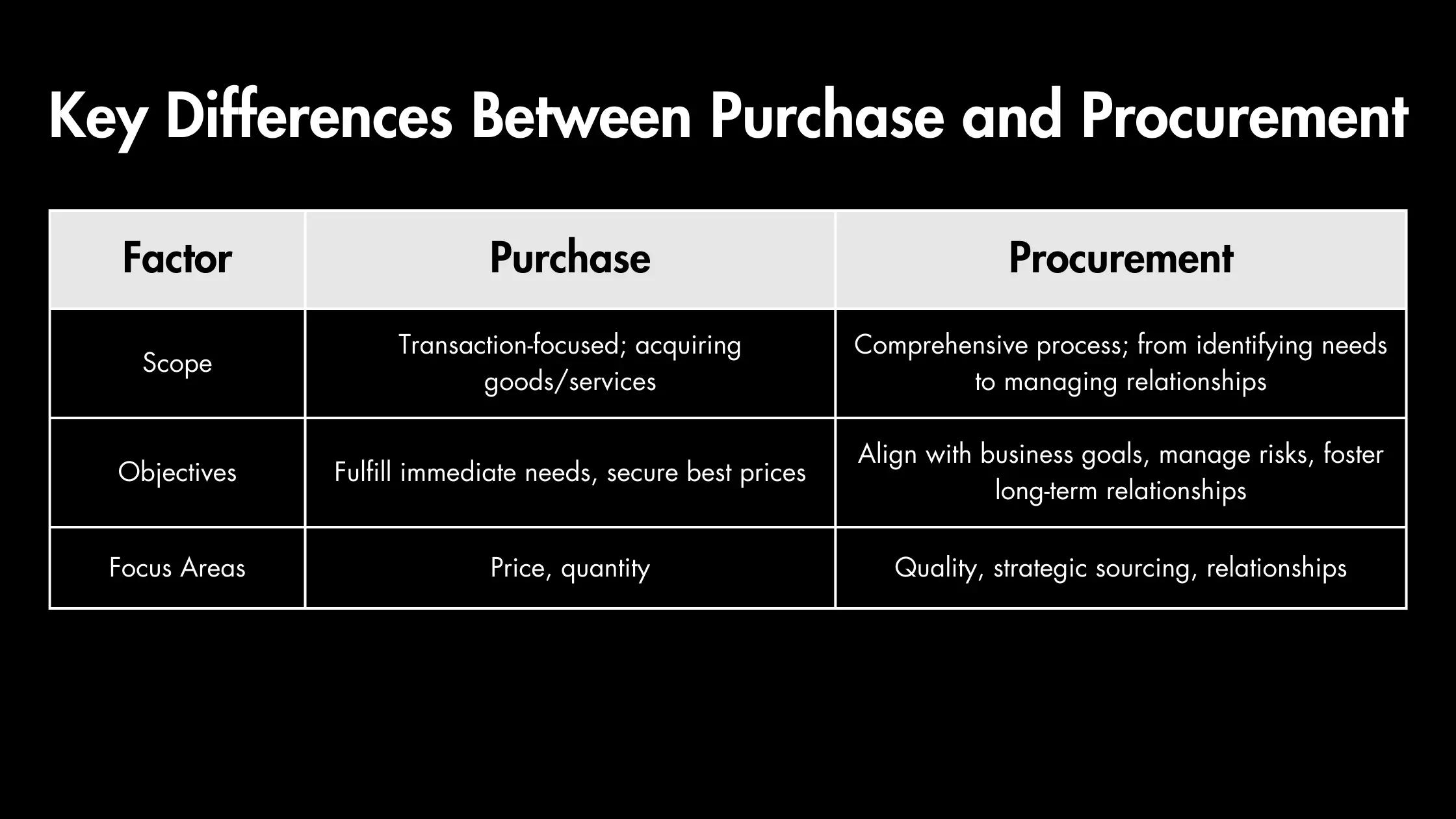

Key Differences – Purchase vs Procurement

Scope

The scope of purchasing is narrower than that of procurement. Purchasing focuses specifically on the transactional aspect of acquiring goods and services, while procurement encompasses the entire process of obtaining these resources—from identifying needs to managing relationships and ensuring value for money.

Objectives

– Purchasing Objectives: The primary objective of purchasing is to fulfill immediate needs for products and services. It aims to secure the best prices for these transactions, prioritizing efficiency and quick response times.

– Procurement Objectives: Procurement is centered around a broader array of objectives, including strategic alignment with organizational goals, risk management, long-term supplier relationships, and achieving value over the entire lifecycle of the supply relationship.

Processes Involved

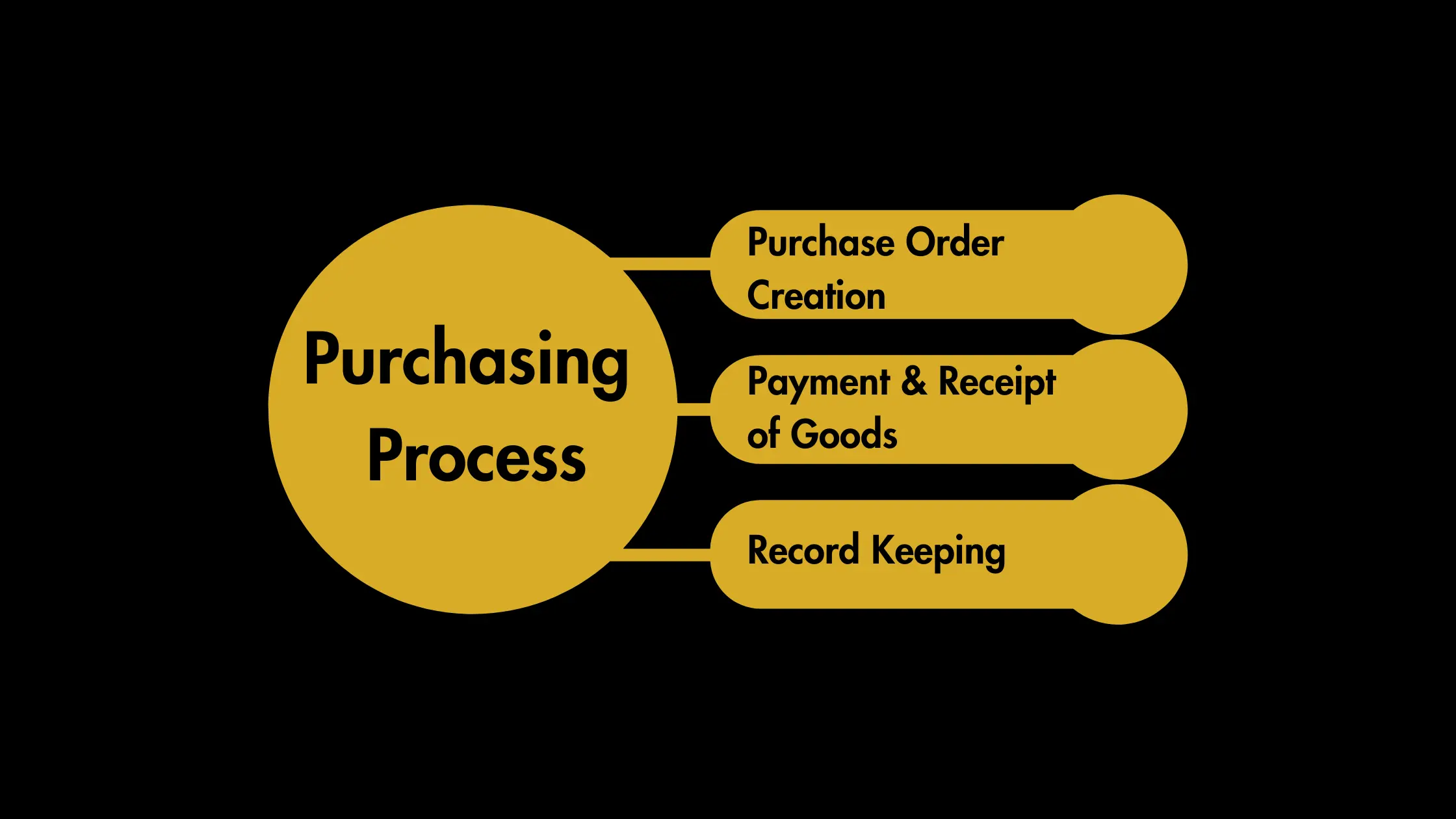

Steps in the Purchasing Process:

1. Purchase Order Creation

2. Payment and Receipt of Goods

3. Record Keeping

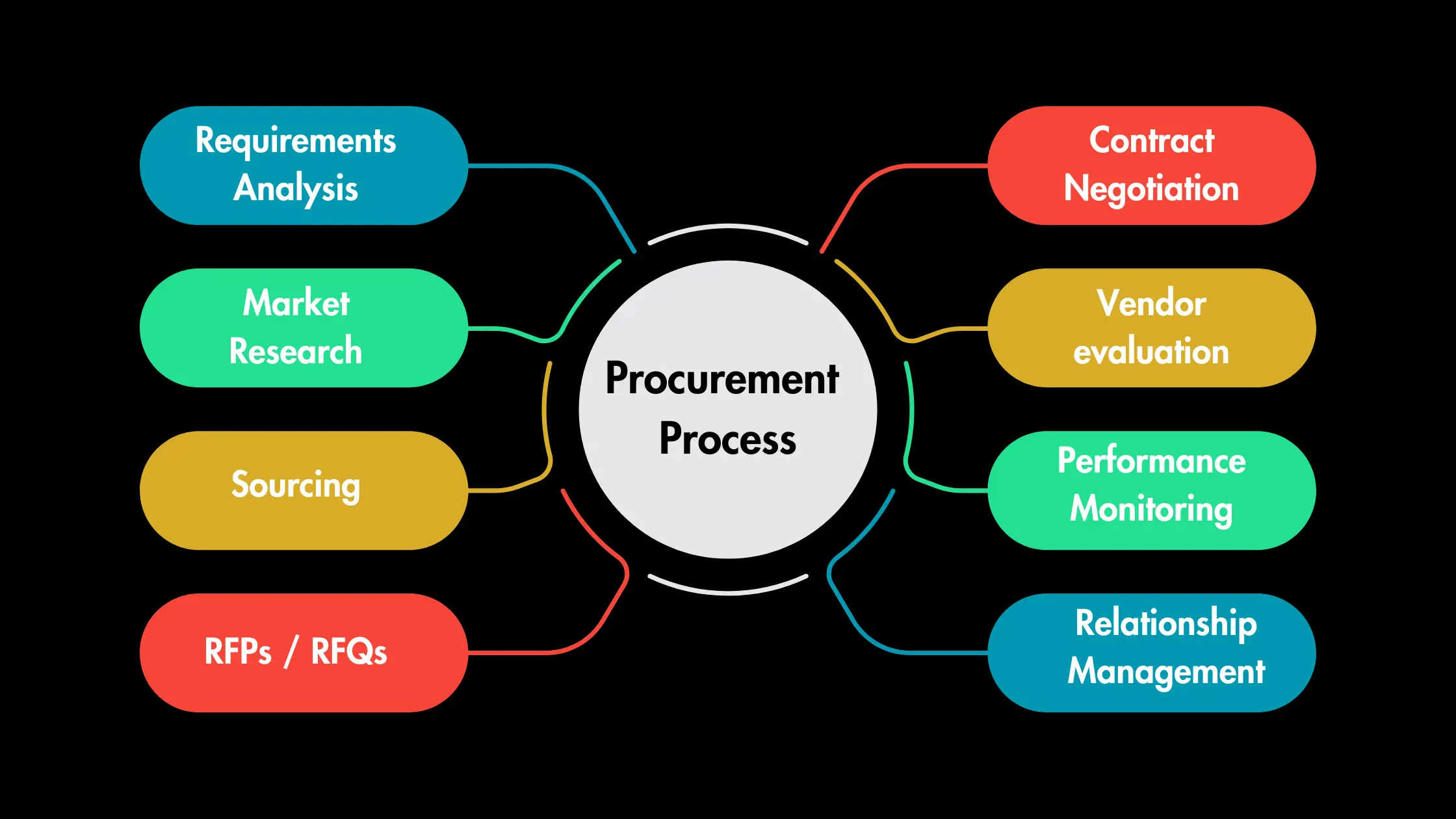

Steps in the Procurement Process:

1. Requirements Analysis

2. Market Research and Supplier Identification

3. Sourcing

4. Request for Proposals (RFP) or Quotations (RFQ)

5. Contract Negotiation

6. Vendor evaluation

7. Supplier Performance Monitoring

8. Relationship Management

Strategic Importance

– Procurement’s Strategic Alignment: The procurement function plays a crucial role in aligning with business strategy by focusing on cost management, supplier collaboration, and inventory optimization. It ensures that the organization not only buys what it needs but does so in a way that enhances overall business performance. Very relevant in Direct procurement.

– Purchasing in Day-to-Day Operations: While purchasing is essential for daily operations, it typically does not engage with long-term strategies. Purchasers execute transactions to meet immediate demands without necessarily considering the bigger picture, such as supplier performance or market shifts. Very relevant in Indirect purchases.

Focus Areas

– Purchasing: The purchasing process typically emphasizes price and quantity. Buyers often seek to minimize costs while ensuring sufficient stock levels to meet operational requirements.

– Procurement: Contrarily, procurement looks beyond price, focusing on quality, strategic sourcing, and relationship management. It aims to create partnerships with suppliers that lead to improved service levels, innovation, and shared risk.

Benefits of Understanding the Distinction

Understanding the Purchase vs Procurement can yield several significant advantages for organizations:

Improved Business Efficiency

By clearly defining purchasing and procurement roles, organizations can eliminate redundancies and ensure that each function operates at its optimal capacity. This clarity leads to smoother operations and quicker decision-making processes.

Better Supplier Relationships

A strategic approach to procurement fosters long-term relationships with suppliers, cultivating trust and collaboration. By engaging suppliers in a more meaningful way, businesses can negotiate favorable terms and secure better service levels.

Enhanced Cost Management and Savings

An integrated strategy that combines effective procurement with tactical purchasing can lead to more significant cost savings. Organizations can benefit from bulk purchasing agreements, volume discounts, and competitive negotiations with suppliers, ultimately enhancing their bottom line.

Strategic Alignment and Risk Management

Organizations that recognize the distinction between purchasing and procurement can align their strategies effectively. Proactive risk management in procurement can help mitigate potential disruptions in supply chains, ensuring a continuous flow of goods and services to meet business needs.

Case Studies and Real-World Examples

Examples of Companies that Effectively Distinguish Between Purchase and Procurement

1. Company X: A global electronics manufacturer utilizes a well-defined procurement strategy that focuses on long-term supplier partnerships. By evaluating suppliers based not only on price but also on quality and innovation, Company X has reduced manufacturing costs and improved product reliability.

2. Company Y: A national retail chain streamlined its procurement process by implementing a centralized procurement unit (CPU). This team engages suppliers in strategic negotiations, category management, reducing costs while also ensuring optimal stock levels across all stores, ultimately enhancing customer satisfaction.

3. Company Z: A pharmaceuticals company adopted an integrated approach to procurement and purchasing by utilizing automated systems for tracking supplier performance and purchasing history. This data-driven strategy led to a significant reduction in lead times and cost per purchase, empowering better decision-making across departments.

Lessons Learned and Key Takeaways

– The Value of Integration: Companies that integrate procurement strategies with purchasing activities tend to see better performance and reduced operational risks.

– Supplier Collaboration is Key: Establishing strong relationships with suppliers fosters trust, leading to more favorable contract negotiations and improved service.

– Data Drives Decisions: Leveraging data analytics enables organizations to make informed decisions that align with both short-term purchasing needs and long-term procurement strategies.

Conclusion

In conclusion, understanding the difference Purchase vs Procurement is essential for any business aiming to achieve efficiency, strategic alignment, and superior supplier relationships. While purchasing focuses on individual transactions to meet immediate needs, procurement encompasses a broader strategic approach aimed at optimizing the entire supply chain process. Recognizing and implementing distinct strategies for each function is vital for enhancing operational effectiveness and long-term business success.